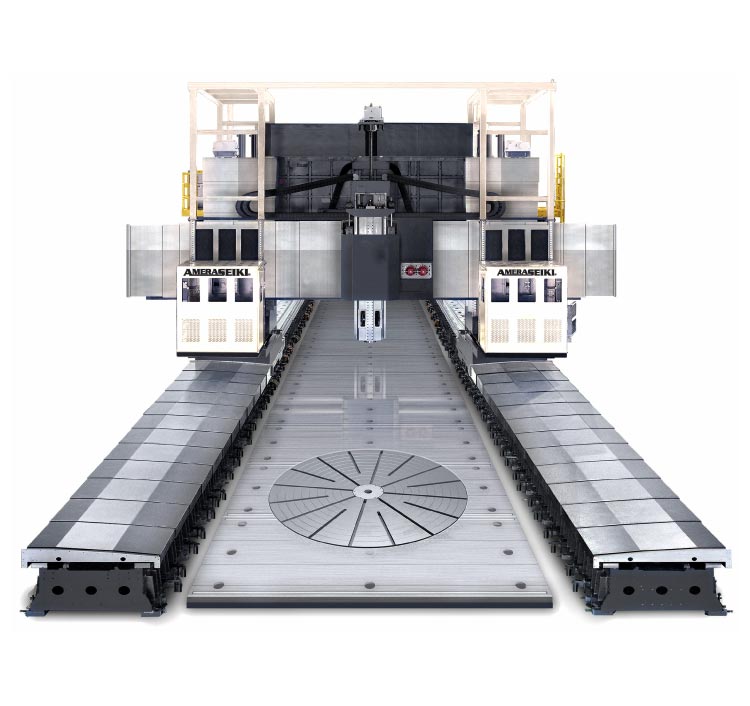

Horizontal Machining Centers

Amera-Seiki Horizontal Machining Centers are built to last, offering a powerful combination of speed and rigidity to users in any industry. Our design begins with a heavily-ribbed, Meehanite casting. Add large diameter ballscrews, a massive oil-cooled spindle and wide-stance ways and you have a rigid, high performance machine tool.

Options such as increased spindle speed, high capacity tool magazines, full 4th axis and various coolant systems allow you to tailor a machine to your specific application. Factory testing that features laser alignment and ball bar tuning assures a high degree of accuracy from the first part cut.

Amera-Seiki’s HMC Series horizontal machining center:

- Our dual-pallet machines offer pallet sizes ranging from 400 to 1,000 mm.

- Heavy base castings provide a strong foundation for outstanding performance.

- Standard configuration allows for one-degree positioning of pallets, but a full B-Axis positioning system is available!

- Our HMCs have spindle speeds up to 10,000 RPM! We can even offer direct drive spindles up to 24,000 RPM!

- We have lots of options available on these machines including higher-capacity ATC with 120 tools and 1,000 PSI coolant through spindle (CTS).

Equipment To Rave About

Horizontal Machining Center Specifications

| Model | Unit | AH-400 | AH-500 | AH-630 | AH-800 | AH-1000 | |

|---|---|---|---|---|---|---|---|

| Travel | X-Axis | mm | 630 | 800 | 1020 | 1270 | 1530 |

| Y-Axis | mm | 630 | 725 | 850 | 1050 | 1250 | |

| Z-Axis | mm | 630 | 725 | 890 | 1050 | 1250 | |

| Spindle Center to Work Table | mm | 50-680 | 50-775 | 70-920 | 50-1100 | 50-1300 | |

| Spindle Nose to Work Table | mm | 130-760 | 150-875 (200-925 w/ BT-50) | 200-1090 | 230-1280 | 230-1480 | |

| Table | Table Surface to Floor | mm | 1100 | 1300 | 1320 | 1370 | |

| Tale Size | mm | 400×400 | 500×500 | 630×630 | 800×800 | 1000×1000 | |

| T-Slot/Bolt Spec | mm | 24-M10 / P1.5×20 | 24-M15 / P2.0 | ||||

| Max Weight on Table | kg | 400 | 500 (opt. 800) | 1200 | 2000 | ||

| Table Indexing | deg | 0.001 | 1 (opt. 0.001) | ||||

| Spindle | Spindle Taper | BT-40 | BT-40 (opt. BT-50) | BT-50 | |||

| Spindle Drive | DDS | Gear Head | |||||

| Spindle Diamenter | mm | 70 | 70 (100 w/ BT-50) | 100 | |||

| Spindle Speed | RPM | 10000 | 8000 (6000 w/ BT-50) | 6000 | |||

| Feedrate | Spindle Motor (cont. 30 min.) | kw | 15/18.5 | 7.5/11 (15/18.5) (22/26) | 15/18.5 (18.5/22) (22/26) | ||

| 3-Axes Cutting Feedrate | M/min | 1-10,000 | 1-6000 | ||||

| 3-Axes Rapid Feedrate | M/min | 36 (opt. 48) | 30 (opt.36) | 24 (opt.30) | 15/15/12 | ||

| ATC | 3-Axes Min. Setting Unit | mm | 0.001 | ||||

| Max. Tool Dia. X Length | mm | 80×300 | 85×300 (125×400 w/ BT-50) | 125×500 | 125×600 | 125 | |

| Max. Tool Weight | kg | 10 | 10 (20 w/ BT-50) | 20 | |||

| Tool Shank | type | P40T-I | P40T-1 (P50T-1 w/ BT-50) | P50T-I | |||

| Tool Change Time | sec | 1.6 | 1.6 (2.9 w/ BT-50) | 2.9 | |||

| APC | Number of Pallets | pcs | 2 | ||||

| Method of Pallet Change | Rotary | ||||||

| Pallet Change Time | sec | 8 | 10 | 12 | |||

| Machine | Floor Space | mm | 3600×4600 | 3835×4835 | 3847×6398 | 3880×8100 | |

| Machine Weight (nominal) | kg | 10,500 | 13,500 (16,000 w/ BT-50) | 27,000 | 30,000 | ||

| Standard Equipment | Chain Type Chip Conveyor | Standard On All Models | |||||

| Chain Type ATC w/ 40 Tool Capacity | |||||||

| Spindle Coolant Curtain | |||||||

| Spindle Oil Cooler | |||||||

| Heat Exchanger for Elec. Cabinet | |||||||

| 3 Zone Chip Flushing System | |||||||

| Automatic Lubrication System | |||||||

| Fully Enclosed Splash Guard | |||||||

| Fanuc Controls | |||||||

| Optional Accessories | Extended Capacity ATC | pcs | 60, 90 or 120 Tools | ||||

| High Speed Spindle | RPM | 10,000-24,000 Direct Drive | 8,000-12,000 Direct Drive | ||||

| 3-Axes Linear Scales | Available On All Models | ||||||

| Oil Skimmer | |||||||

| A/C For Electrical Cabinet | |||||||

| Auto. Tool Length Measuring Device | |||||||

| Coolant Through Tool Holder | |||||||

Quality Service & Support

Our highly-trained staff is here and ready to service CNC machines. Amera-Seiki also carries an industry-leading parts inventory.

Our Services

Innovative CNC Technology

Amera-Seiki constantly evolves to provide you with the latest in machine productivity and features. We remain on the cutting edge of machine tool technology.

About Us

Explore Our Machines

Amera-Seiki has decades of experience building a large variety of CNC machines. No matter your need, we have the machine.

Our Machines