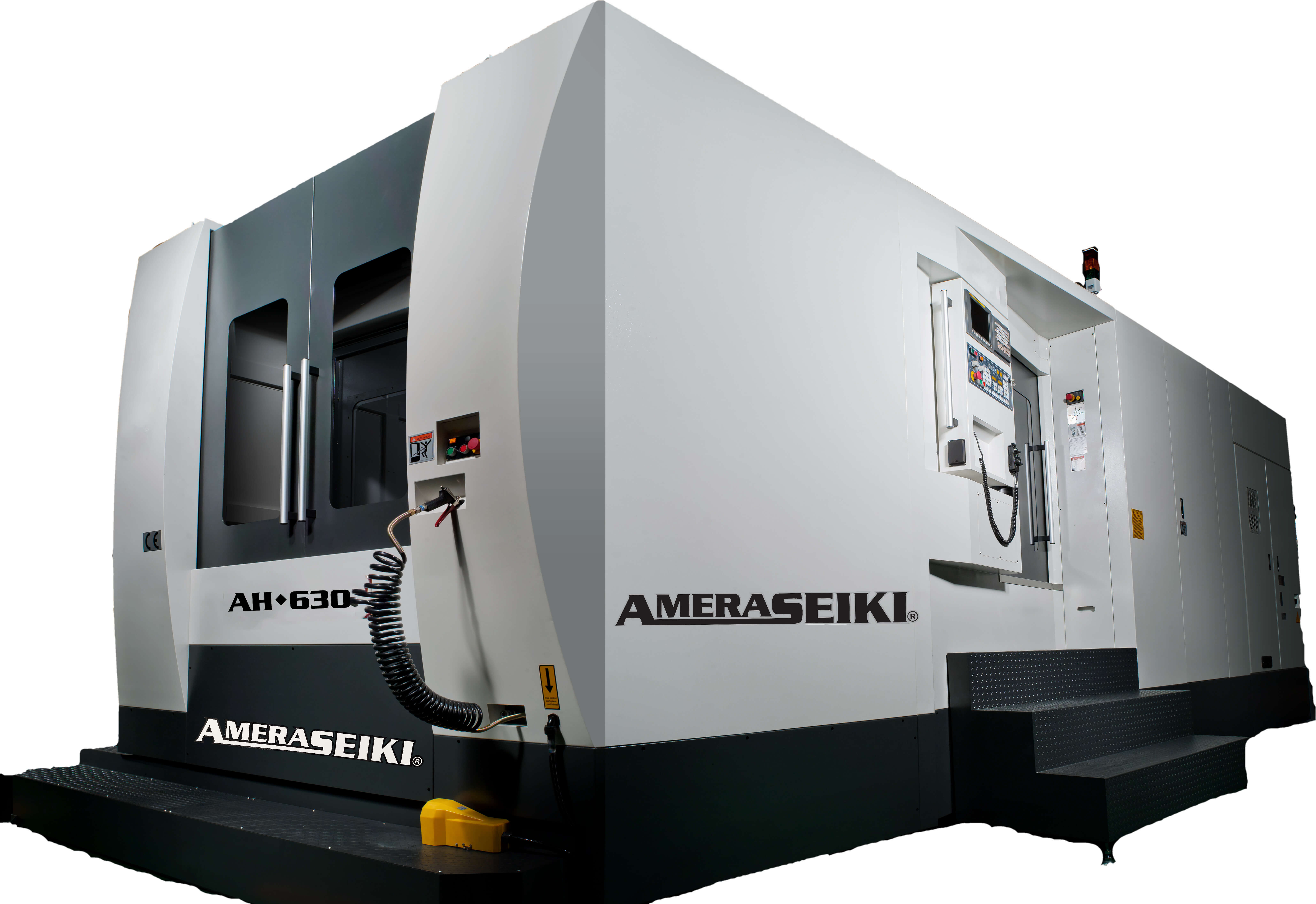

Horizontal Machining Centers

Amera-Seiki Horizontal Machining Centers are built to last, offering a powerful combination of speed and rigidity to users in any industry. Our design begins with a heavily-ribbed, Meehanite casting. Add large diameter ballscrews, a massive oil-cooled spindle and wide-stance ways and you have a rigid, high performance machine tool.

Options such as increased spindle speed, high capacity tool magazines, full 4th axis and various coolant systems allow you to tailor a machine to your specific application. Factory testing that features laser alignment and ball bar tuning assures a high degree of accuracy from the first part cut.