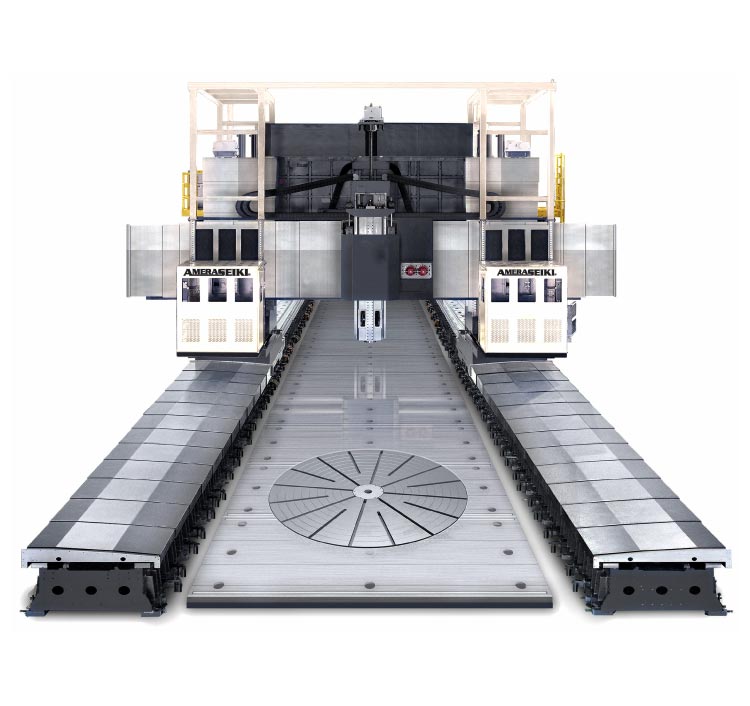

Vertical Turning Lathes

Amera-Seiki’s Vertical Turning Lathe (VT Series) was designed with the high output user in mind. Our turret style machines feature high torque drives for your toughest cuts, while our ram style machine provides a greater level of support to enhance accuracy and finish.

Massive castings and extra-wide way systems assure accurate and stable machining on all of our vertical turning lathes. Heavy duty transmissions, which are standard on larger models, allow stock removal at high spindle speeds.

Our feed system provides superior vibration absorption and chatter-free cutting, even under demanding conditions such as threading, grooving, interrupted cuts and heavy roughing. With chuck sizes ranging from 20 inches to 13 feet, Amera-Seiki has a Vertical Turning Lathe to process your workpiece.

Amera-Seiki’s VTL Series vertical turning lathes:

- We offer both Turret and Ram style machines!

- We specialize in very large machines with table diameters up to 4 meters and max swing diameters up to 4.5 meters!

- Cutting heights up to 2.5 meters!

- Have a very heavy work piece? We have chucks that can handle up to 80,000 kg (88 us ton)!

- Need full C-Axis with live tooling? We can do it! With up to a 50 HP live tooling!

- Our high density castings are heavier with less webbing. This means less harmonics and less thermal variation!

- We have a wide array of options like a 3-speed gearbox and even dual ram capability!!

Equipment To Rave About

VT Series Turret Style Specifications

| Item | Description | Model | VT-500T | VT-500TM | VT-650T | VT-650TM | VT-800T | VT-800TM | VT-1000T | VT-1000TM | VT-1100T | VT-1100TM | VT-1200T | VT-1200TM |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Working Space | Max Swing Diameter | mm | 720 | 750 | 850 | 1150 | 1350 | 1350 | ||||||

| Max Cutting Diameter | mm | 550 | 650 | 800 | 1000 | 1100 | 1200 | |||||||

| Max Cutting Height | mm | 450 | 700 | 800 | 800 | 800 | 800 | |||||||

| Main Spindle | Dia. Of Spindle Bearing | mm | 130TAC-A8 | 160TAC-A8 | 170TAC-A11 | 220TAC-A15 | 220 | 220 | ||||||

| Spindle Nose | A2-8 | A2-11 | A2-11 | A2-15 | ||||||||||

| Max. Spindle Turning RPM | RPM | 2500 | 2000 | 1500 | 1000 | 800 | 1000 | |||||||

| Turret | Turret Type | 100-8T | TBMA250 | 160-8T | TBMA250 | 160-8T | 200-8T | TBMA320 | 200-8T | TBMR320 | 200-8T | TBMR320 | ||

| Tools | pcs | 8 | 12 | 8 | 12 | 8 | 12 | 8 | 12 | 8 | 12 | 8 | 12 | |

| Tool Size | mm | 32ѱ50 | 25ѱ40 | 32ѱ50 | 32ѱ60 | 32ѱ50 | 32ѱ60 | 32ѱ50 | 32ѱ60 | |||||

| Axis Traveling and feedrate | X-Max Travel | mm | 20-290 | 30-390 | 35-460 | 60-570 | 60-640 | |||||||

| Z-Max Travel | mm | 450 | 650 | 850 | ||||||||||

| X-Rapid Feedrate | mm/min | 15000 | 12000 | |||||||||||

| Z-Rapid Feedrate | mm/min | 15000 | 12000 | |||||||||||

| Power | Spindle Motor | kw | ɑ p30 15/18.5 | ɑ p40 18.5/22 | ɑ p40 37/45 | |||||||||

| Live Tool Motor | kw | N/A | ɑ 8 7.5/1 | N/A | ɑ 8 7.5/1 | N/A | ɑ 8 7.5/1 | N/A | ɑ 12 11/15 | N/A | ɑ 12 11/15 | N/A | ɑ 12 11/15 | |

| X-Axial Servo Motor | kw | 1.6 | 3 | 4 | 7 | |||||||||

| Z-Axial Servo Motor | kw | 3 | 4 | 7 | ||||||||||

| Oil Hydraulic Motor | kw | 2.2 | ||||||||||||

| Coolant Motor | kw | 2.6 | ||||||||||||

| Machine Bed Flushing Water | kw | 0.75 | 0.75 + 0.75 | |||||||||||

| Chip Conveyor Motor | kw | 0.2 | ||||||||||||

| Machine Layout | Machine Size | mm | 2300×3400 | 3100×2440 | 3200×2680 | 3750×3250 | 3950×3500 | 4350×3550 | ||||||

| Machine Height | mm | 2460 | 2900 | 3135 | 3550 | 3550 | 3750 | |||||||

| Machine Weight | kg | 6900 | 8000 | 8700 | 13500 | 15400 | 16500 | |||||||

| Power Required | kva | 35 | 40 | 40 | 50 | 40 | 50 | 60 | 70 | 60 | 70 | 60 | 70 | |

| Control System | Fanuc 0iT-D | |||||||||||||

| Standard Accessories | 3-Jaw Hydraulic Chuck | inch | 15 (18-21 avail) | 15 (18-24 avail) | 21 (24-32 avail) | 32 (40 avail) | 40 | |||||||

| Facing/Boring Tool Holder | pcs | 3/3 | 3/3 | 3/3 | 3/3 | 3/3 | 3/3 | |||||||

| Outer/Inner Tool Turret | pcs | 2/2 | 2/2 | 2/2 | 2/2 | 2/2 | 3/3 | |||||||

| Turret | pcs | ѱ 20, 25, 32, 40 | ||||||||||||

| Hydraulic Unit | Included with all models | |||||||||||||

| Chip Conveyor | ||||||||||||||

| Coolant System | ||||||||||||||

| Disk Type Oil/Water Seperator | ||||||||||||||

| Heat Transfer for Electric Cabinet | ||||||||||||||

| Work Lamp & 3-Color Alarm Lamp | ||||||||||||||

| Automatic Lubrication System | ||||||||||||||

| Optional Accessories | Spindle Motor Upgrade | kw | ɑ 40 37/45 | ɑ 50 45/55 & ɑ 60 60 | ||||||||||

| Control System | Fanuc 32iT | |||||||||||||

| Manual Guide i | Available on all models | |||||||||||||

| High Pressure Flood Coolant | ||||||||||||||

| 2-Speed Gearbox | ||||||||||||||

| Auto Door | ||||||||||||||

| Electrical Cabinet A/C system | ||||||||||||||

| Paper Filter | ||||||||||||||

| Oil Mist Filter | ||||||||||||||

| Caliper Unit Tools | ||||||||||||||

| Power Stabilizer | ||||||||||||||

| Robert Interference Device | ||||||||||||||

| CE Mark | ||||||||||||||

VT Series Ram Style Specifications

| Item | Model | VT-1250R | VT-1250RM | VT-1600R | VT-1600RM | VT-2000R | VT-2000RM | VT-2500R | VT-2500RM | VT-3200R | VT-3200RM | VT-4500R | VT-4500RM | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Table Size | Table Diameter | mm | §1250 | §1600 | §2000 | §2500 | §3200 | §4000 | ||||||

| Table Max. Swing Diameter | mm | §1350 | §1700 | §2100 | §2800 | §3400 | §4500 | |||||||

| Table Max. Cutting Diameter | mm | §1250 | §1600 | §2000 | §2500 | §3200 | §4000 | |||||||

| Table Max. Cutting Height | mm | 1000 | 1600 | 2500 | ||||||||||

| Cross Rail Moving Height Cross Travels |

mm | 600 (4 steps) | 1000 (6 Steps) | 1250 (6 Steps) | 1600 (5 steps) | |||||||||

| Table Weight Capacity/ Table Max. Load |

kg | 6000 | 12000 | 20000 | 30000 | 40000 | 80000 | |||||||

| Spindle | Main Spindle Speed/ Table Speed |

rpm | 1-560 | 10-400 | 10-300 | 10-260 | 10-190 | 80 | ||||||

| Gear Box Speed Stages | step | 3 | 3 | |||||||||||

| Live Spindle Speed/ Milling Spindle Speed |

RPM | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | |||||||

| Ram Size | mm² | 220X220 | 254×254 | 305×305 | ||||||||||

| ATC System | ATC Positions – Standard | 12 (24 opt) | 16 (24 Opt.) | 12 (24 Opt.) | 12 (60 Opt.) | |||||||||

| Tool Specification | mm | □25 □32 □40 | ||||||||||||

| Tool Shank Size/Type | mm | 220×220 | 200×200 | 300×300 | 300×300/BT-50 | 300×300 | 300×300/BT-50 | 300×300 | 300×300/BT-50 | 300×300 | 300×300/BT-50 | 305×240 | 305×240/BT-50 | |

| Feed Rate | Rapid Feed Rate (X-Axis) | m/min | 12 | 10 | ||||||||||

| Rapid Feed Rate (Z-Axis) | m/min | 12 | 10 | |||||||||||

| X-Axis Travel | mm | 300-950 | 300-1200 | 300-1700 | 300-2100 | 500-2200 | 500-2700 | |||||||

| Z-Axis Travel | mm | 800 | 1250 | 1600 | ||||||||||

| Cutting Feed Rate (X/Z) | mm/rev | 0.01-1000 | 0.01-1000 | |||||||||||

| Controller | Standard CNC Control (Fanuc) | Fanuc Oi-TD/31i-TB | ||||||||||||

| Siemens | 840D | |||||||||||||

| Motor Size | Main Spindle Motor | kw(HP) | ɑ 40 37 (45) | ɑ 50 37 (45) | ɑ 60 60 (80) | ɑ 120(120/160) | ||||||||

| Axes Motor | kw(HP) | ɑiF30 7 (10) | ɑiS30 5.5 (7.4) | |||||||||||

| Live Spindle Motor/ Milling Spindle Motor |

kw (HP) | ɑ 12Hvi (11/15) | ɑ iF229 (28/37) | ɑ iF229 (28/37) | ɑ iF229 (28/37) | class=”grey” | ɑ iF229 (28/37) | ɑ iF229 (28/37) | ||||||

Quality Service & Support

Our highly-trained staff is here and ready to service CNC machines. Amera-Seiki also carries an industry-leading parts inventory.

Our Services

Innovative CNC Technology

Amera-Seiki constantly evolves to provide you with the latest in machine productivity and features. We remain on the cutting edge of machine tool technology.

About Us

Explore Our Machines

Amera-Seiki has decades of experience building a large variety of CNC machines. No matter your need, we have the machine.

Our Machines