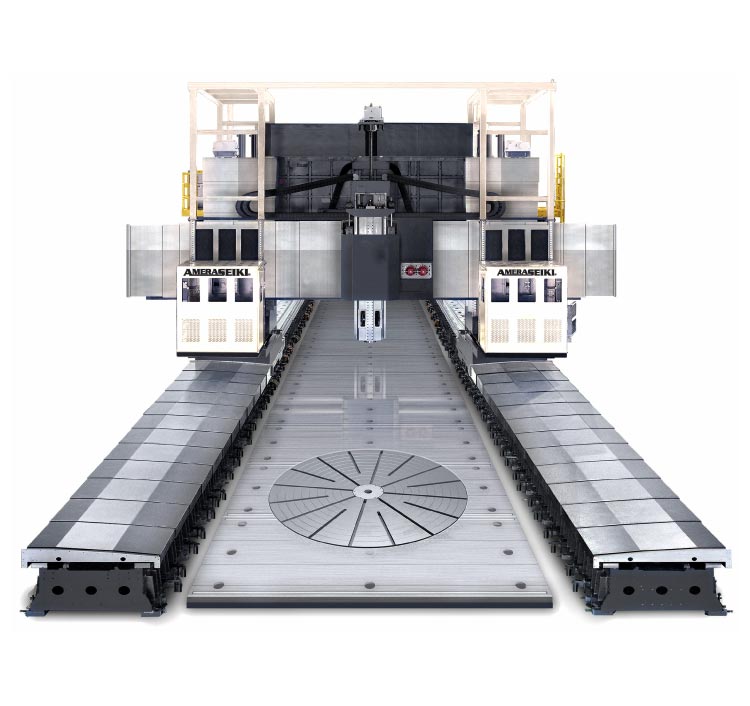

Vertical Traveling Column Mill (VTC)

Do you need higher efficiency than a traditional Vertical Machining Center can offer? With our VTC, the table is fixed and all XYZ machine movement happens in the column.The larger table allows you to place multiple workpieces at one time, reducing your load/unload time.With a partition, you can even load one side of the table while the machine is working on the opposite side.

The fixed table also allows you to work on extremely long, heavy pieces that can’t be attached safely to the moving table on a traditional bridge mill or machining center. We offer our VTC in two sizes to best meet your machining requirements. See the specifications page to find out if Amera-Seiki’s Vertical Traveling Column mill is the best machine for your job!

Amera-Seiki’s VTC Series vertical travelling column mills:

- Amera-Seiki offers two models of VTC: the VTC-5 with a table size of 2500 x 600 mm and the VTC-7 with a table size of 3500 x 600 mm.

- This fixed-table machine utilizes the column for travels on X-, Y- and Z-Axes!

- We have spindle speeds from 6,000 to 10,000 RPM.

Equipment To Rave About

Specifications

| Model | Unit | VTC-5 | VTC-7 | |

|---|---|---|---|---|

| Travel | X-Axis | mm | 2200 | 3200 |

| Y-Axis | mm | 620 | 720 | |

| Z-Axis | mm | 620 | 620 | |

| Spindle Nose to Table Surface | mm | 120 – 740 | 120 – 740 | |

| Spindle Center to Column Surface | mm | 690 | 790 | |

| Table | Dimension | mm | 2500×600 | 3500×600 |

| T-Slots: Width/Number/Pitch | mm | 18 / 5 / 125 | 18/5/125 | |

| Table Height From Floor | mm | 830 | 830 | |

| Max. Table Load | kg | 1800 | 2500 | |

| Headstock | Spindle Type | BT 40, CAT 40 | ||

| Spindle Speed | RPM | 8000 (opt. 10,000) | ||

| Feedrate | Rapid Feed for X/Y/Z Axis | mm/min | 32,000 | |

| Cutting Feed for X/Y/Z Axis | mm/min | 1 – 10,000 | ||

| Power | Spindle Motor, Contin./30 Min. | kw | 11/15 | |

| AC Servo Motor, X/Y/Z | kw | 35./2.0/2.0 | ||

| Coolant System | W | 580 | ||

| Lubrication System | W | 25 | ||

| Spindle Chiller System | W | 850 (spindle over 8000 RPM) | ||

| ATC | Tool Capacity, Arm Type Magazine | pcs | 24/32/40 | |

| Max. Tool Diameter | mm | 70 (Adjascent space empty: 127) | ||

| Max. Tool Length | mm | 300 | ||

| Max. Tool Weight | kg | 7 | ||

| Accuracy | Positioning | mm | 0.005 ±0.0002 | |

| Repeatability | mm | 0.005 ±0.0002 | ||

| General Information | Machine Weight | kg | 14,200 | 23,780 |

| Machine Dimensions | mm | 4068x5810x3000 | 4168x6810x3000 | |

| Source Air Pressure | kg/cm² | 5 | 5 | |

| Controller | Fanuc Oi-MB | |||

| Standard Equipment | Full Enclosure Guard | Standard on all models | ||

| Rigid Tapping | ||||

| Remote Handwheel | ||||

| Halogen Work Light | ||||

| Beacon Light | ||||

| Auto. Power Off | ||||

| Auto Lube System | ||||

| Spindle Air Purge System | ||||

| Spindle Air Blow System | ||||

| Coolant System | ||||

| Heat Exchanger for Electrical Box | ||||

| Optional Accessories | Controller: Fanuc 18i MB, 21i MB, Heidenhein | Available on all models | ||

| 10,000/12,000 RPM Spindle w/ Chiller | ||||

| Coolant Through Spindle (CTTS) | ||||

| ZF-2 Gear Head with Oil Chiller | ||||

| Chip Flushing System | ||||

| Chain Type Chip Conveyor | ||||

| 4th Axis Interface | ||||

Quality Service & Support

Our highly-trained staff is here and ready to service CNC machines. Amera-Seiki also carries an industry-leading parts inventory.

Our Services

Innovative CNC Technology

Amera-Seiki constantly evolves to provide you with the latest in machine productivity and features. We remain on the cutting edge of machine tool technology.

About Us

Explore Our Machines

Amera-Seiki has decades of experience building a large variety of CNC machines. No matter your need, we have the machine.

Our Machines