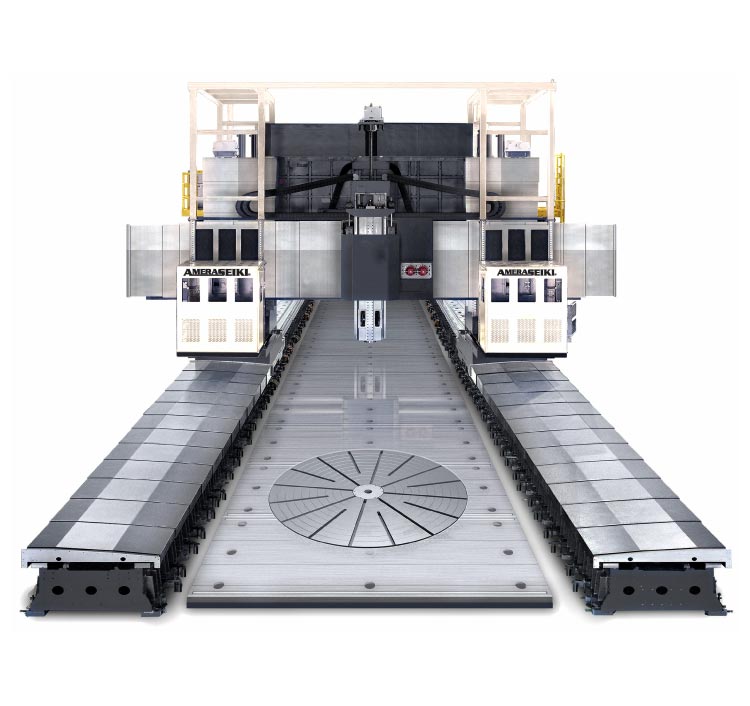

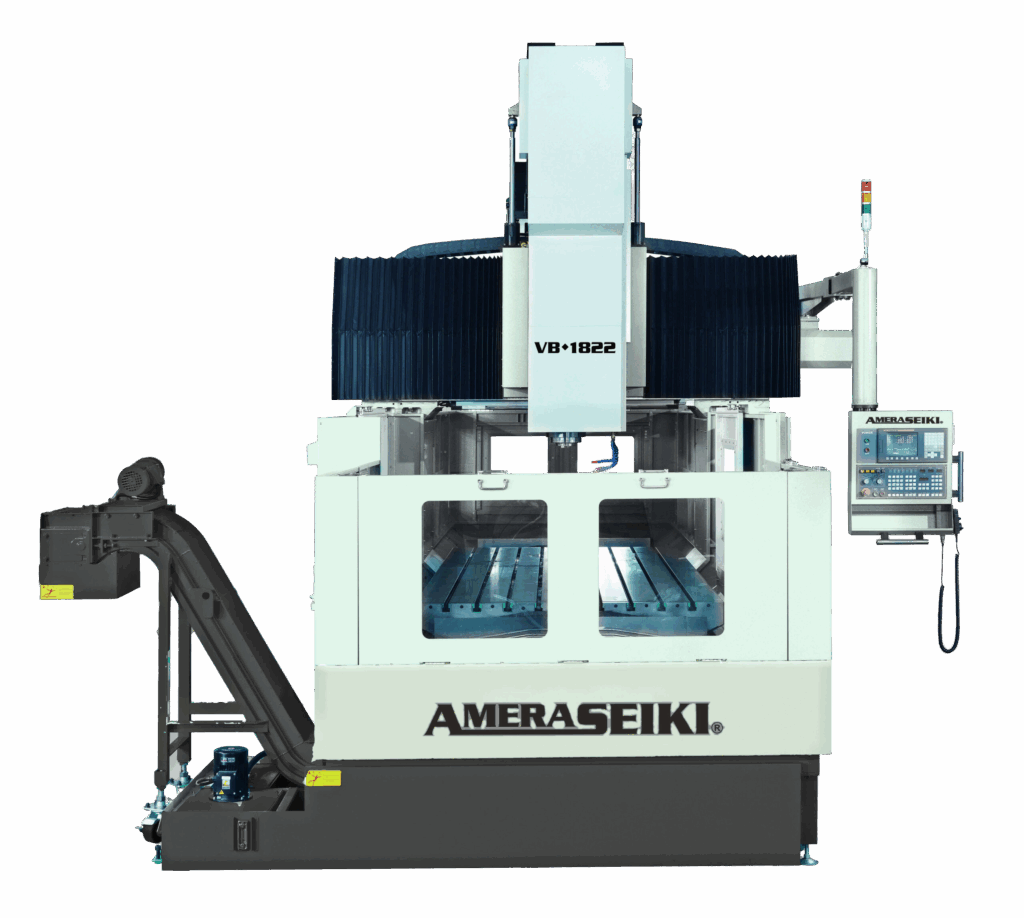

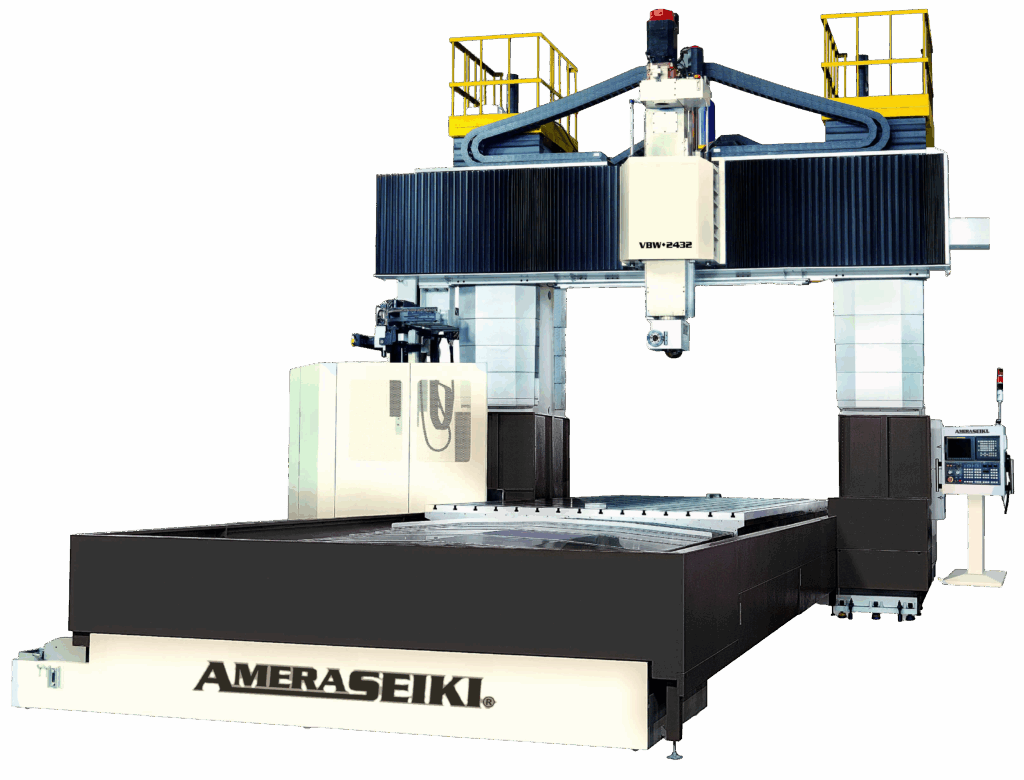

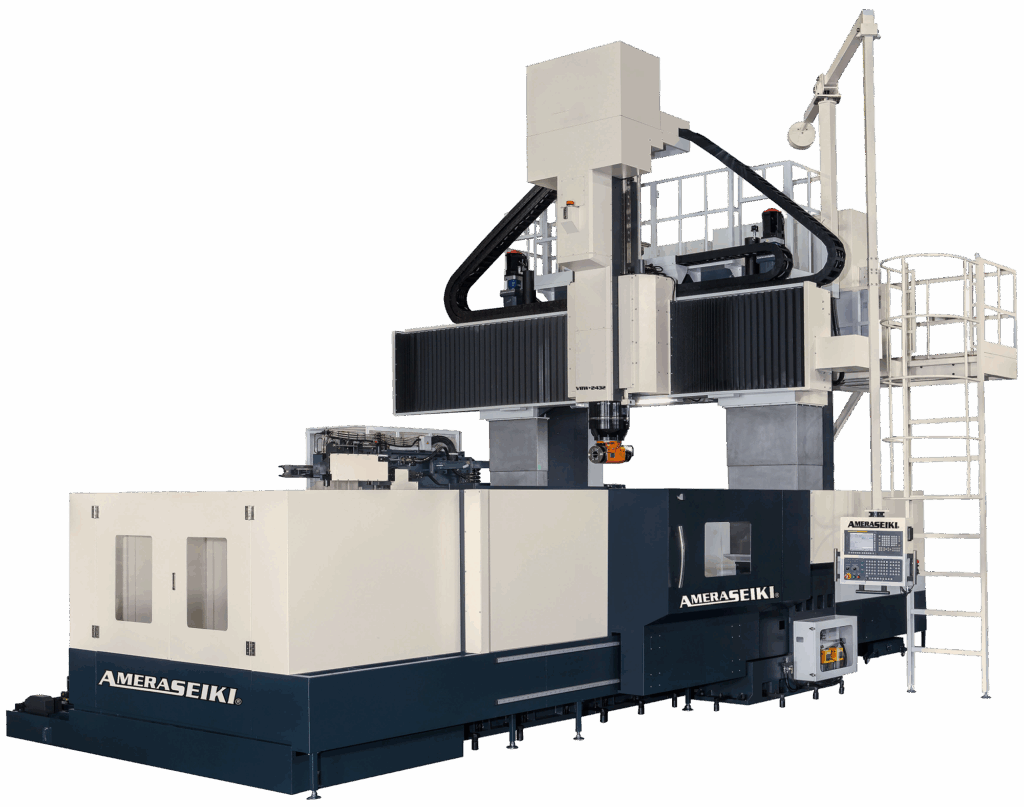

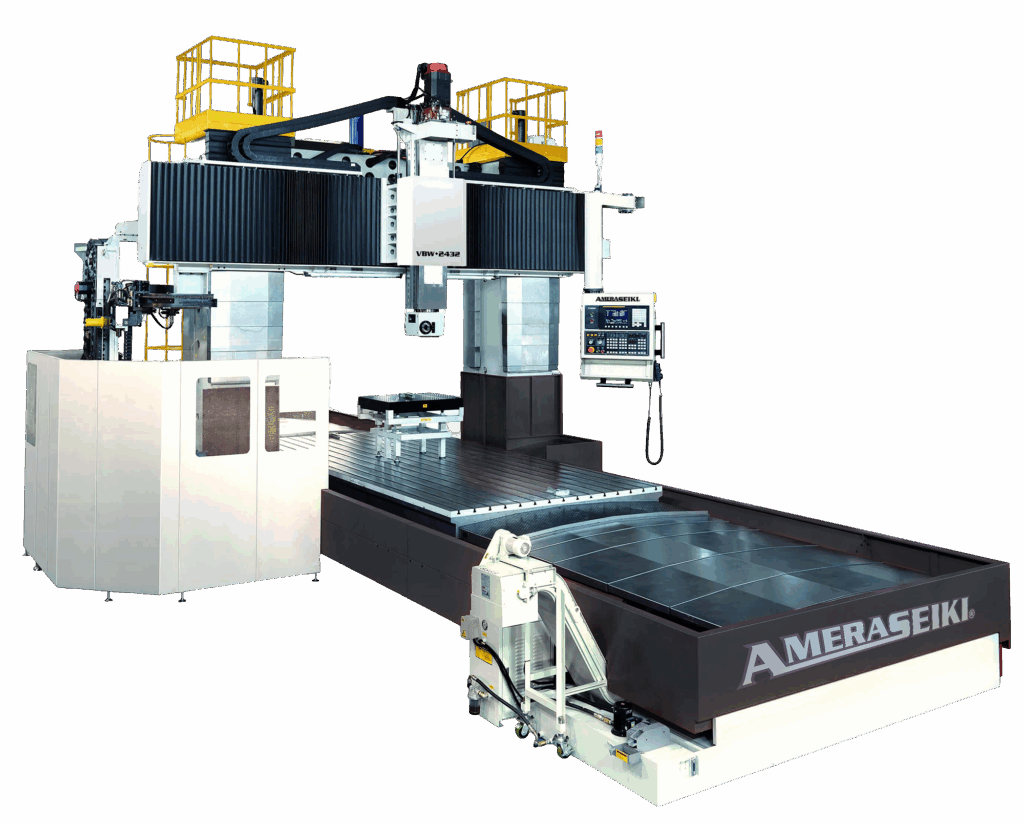

Vertical Bridge Mills

When you need a machine tool to process your mid to large size parts, look no further than Amera-Seiki. Our Vertical Bridge Mill line offers the strength and speed to make short work of your toughest jobs.

We start with massive Meehanite castings, annealed to eliminate deformation caused by internal warpage and stress. A quiet two-speed spindle, driven by a powerful Fanuc motor, offers a winning combination of high speed and torque.

Our fully sealed, immersion-type lubrication system with standard oil chiller circulates coolant and keeps the machine running cool at high RPM. The rigid ball screws and powerful servo drives assure smooth cutting.

Top Quality Vertical Bridge Mills

- 48 Machine sizes to choose from! Our VB Series bridge mills can handle very large work pieces with X-Axis travels from 2.2 to 8.0 Meters and Y-Axis travels from 1.4 to 4.2 Meters!

- Our base castings are 25% heavier than our competitors. This provides greater structural rigidity to reduce harmonics or chatter.

- Need to change heads automatically? We offer Automatic Head Changers with up to 10 head capacity so we can accommodate right angle heads, swivel heads, extension heads and many, many more.

- Doing a complex piece and need 5-Axis Simultaneous machining? We can do it with Fanuc, Siemens or Heidenhain controls, with up to 24,000 RPM utilizing HSK tooling!

- Have a taller workpiece? We offer a W-Axis to extend the vertical travel!

Equipment To Rave About

VB Series Specifications

| Item | Unit | VB-14 Series | VB-18 Series | VB-21 Series | VB-24 Series | VB-28 Series | VB-32 Series | VB-36 Series | VB-42 Series | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | VB- | 1422 | 1427 | 1432 | 1822 | 1827 | 1832 | 1842 | 1852 | 2132 | 2142 | 2152 | 2432A | 2442A | 2452A | 2832 | 2842 | 2852 | 2860 | 3232 | 3242 | 3252 | 3260 | 3642 | 3652 | 3660 | 4242 | 4252 | 4260 | |

| Distance between Columns (without splash guard) | mm | 1400 | 1850 | 2150 | 2450 | 2850 | 3250 | 3650 | 4250 | |||||||||||||||||||||

| Table Size | Length | mm | 2000 | 2500 | 3000 | 2000 | 2500 | 3000 | 4000 | 5000 | 3000 | 4000 | 5000 | 3000 | 4000 | 5000 | 3000 | 4000 | 5000 | 6000 | 3000 | 4000 | 5000 | 6000 | 4000 | 5000 | 6000 | 4000 | 5000 | 6000 |

| Width | mm | 1300 | 1500 | 1800 | 2000 | 2200 | 2600 | 3000 | ||||||||||||||||||||||

| Maximum Table Load | ton | 8 | 9 | 10 | 12 | 13 | 15 | 18 | 20 | 15 | 18 | 20 | 15 | 18 | 20 | 18 | 18 | 20 | 22 | 18 | 18 | 20 | 22 | 20 | 22 | 24 | 20 | 22 | 24 | |

| T-slot | Width x Pitch x No. | mm | 22 x 150 x 7 | 22 x 150 x 9 | 22 x 150 x 11 | 22 x 150 x 13 | 28 x 180 x 11 | 28 x 2000 x 13 | 28 x 2000 x 15 | |||||||||||||||||||||

| Travel | X – axis | mm | 2200 | 2700 | 3200 | 2200 | 2700 | 3200 | 4200 | 5200 | 3200 | 4200 | 5200 | 3200 | 4200 | 5200 | 3200 | 4200 | 5200 | 6000 | 3200 | 4200 | 5200 | 6000 | 4200 | 5200 | 6000 | 4200 | 5200 | 6000 |

| Y – axis | mm | 1300 | 1800 | 2100 | 2400 | 2800 | 3200 | 3600 | 4200 | |||||||||||||||||||||

| Z – axis | mm | 800 | 800 (Optional 1100) | 800 (Optional 1100) | 1100 (Optional 1400) | |||||||||||||||||||||||||

| Spindle | Nose to table | mm | 100 ~ 900 | 200 ~ 1000 (200 ~ 1300) |

100 ~ 900 (100 ~ 1200) |

200 ~ 1000 (200 ~ 1300) |

100 ~ 900 (100 ~ 1200) |

100 ~ 900 (100 ~ 1200) |

300 ~ 1400 (300 ~ 1700) |

|||||||||||||||||||||

| Center to Column | mm | 380 | 430 | 430 | ||||||||||||||||||||||||||

| Taper / Speed / Power | RPM / kW | BT50 / 6,000 – 18.5K / 22kW | BT50 / 6,000 – 22K / 26kW | |||||||||||||||||||||||||||

| Feedrate | Cutting | mm/min | 5 ~ 12,000 | 5 ~ 10,000 | ||||||||||||||||||||||||||

| X – axis G00 | m/min | 24 | 22 | 22 | 24 | 22 | 20 | 18 | 15 | 20 | 18 | 15 | 20 | 18 | 15 | 15 | 12 | 10 | 10 | 15 | 12 | 10 | 10 | 12 | 10 | 10 | 12 | 10 | 10 | |

| Y / Z – axis G00 | m/min | 24/20 | 20/15 | 15/15 | 12/15 | |||||||||||||||||||||||||

| Accuracy (JIS 6338) | mm | Positioning ±0.015 / full travel; Repeatability ±0.003 | Positioning ±0.015 / full travel; Repeatability ±0.003 | |||||||||||||||||||||||||||

| ATC & Tool Magazine | Capacity / Dia | mm | Cam type ATC 24pcs / Max. Dia. Ø110 (full tools); Ø200 (adjascent pocket empty) | Cam type ATC 24pcs | Chain type ATC 32pcs / Max. Dia. Ø125 (full tools); Ø220 (adjascent pocket empty) | |||||||||||||||||||||||||

| Max tool weight / Length | Kg/mm | 18kg / 350mm | 20kg / 400mm | |||||||||||||||||||||||||||

| Tool selection | Take shortest direction / M24 P3.0 – 45° | Take shortest direction / M24 P3.0 – 45° | ||||||||||||||||||||||||||||

| Power / Pneumatic | 40 ~ 50 KVA / 6.5 kg/cm² | 50 ~ 60 KVA / 6.5 kg/cm² | ||||||||||||||||||||||||||||

| Machine Size | Length | mm | 6400 | 7400 | 8400 | 6400 | 7400 | 8400 | 11100 | 13100 | 8400 | 11100 | 13100 | 8400 | 11100 | 13100 | 9400 | 11400 | 13400 | 15400 | 9400 | 11400 | 13400 | 15400 | 11400 | 13400 | 15400 | 11400 | 13400 | 15400 |

| Width | mm | 3450 | 4550 | 4850 | 5150 | 6000 | 6400 | 6800 | 7400 | |||||||||||||||||||||

| Height | mm | 4050 | 4570 (5470) | 5500 (6400) | ||||||||||||||||||||||||||

| Machine Weight (app.) | ton | 20 | 22 | 25 | 25 | 28 | 32 | 38 | 43 | 33 | 38 | 43 | 35 | 42 | 45 | 47 | 52 | 57 | 62 | 50 | 55 | 60 | 65 | 58 | 63 | 68 | 63 | 68 | 73 | |

VBW Series Specifications

| Item | Unit | VBW-24 Series | VBW-28 Series | VBW-32 Series | VBW-36 Series | VBW-42 Series | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | VBW- | 2432 | 2442 | 2452 | 2460 | 2832 | 2842 | 2852 | 2860 | 3242 | 3252 | 3260 | 3642 | 3652 | 3660 | 4242 | 4252 | 4260 | |

| Distance between Columns (without splash guard) | mm | 2450 | 2850 | 3250 | 3650 | 4250 | |||||||||||||

| Table Size | Length | mm | 3000 | 4000 | 5000 | 6000 | 3000 | 4000 | 5000 | 6000 | 4000 | 5000 | 6000 | 4000 | 5000 | 6000 | 4000 | 5000 | 6000 |

| Width | mm | 2000 | 2200 | 2600 | 3000 | ||||||||||||||

| Maximum Table Load | ton | 18 | 18 | 20 | 22 | 18 | 18 | 20 | 22 | 18 | 20 | 22 | 20 | 22 | 24 | 20 | 22 | 24 | |

| T-slot | Width x Pitch x No. | mm | 28 x 180 x 11 | 28 x 180 x 11 | 28 x 200 x 13 | 28 x 200 x 15 | |||||||||||||

| Travel | X – axis | mm | 3200 | 4200 | 5200 | 6000 | 3200 | 4200 | 5200 | 6000 | 4200 | 5200 | 6000 | 4200 | 5200 | 6000 | 4200 | 5200 | 6000 |

| Y – axis | mm | 2400 | 2800 | 3200 | 3600 | 4200 | |||||||||||||

| Z – axis | mm | 800 (100) | 1100 (1400) | ||||||||||||||||

| W – axis | mm | 1000 (1500)Every 250mm positioning | 1000 (1500/2000) Every 250mm positioning | ||||||||||||||||

| Spindle | Nose to table | mm | 100 ~ 800 (2100) | 100 ~ 2100 (2400) | |||||||||||||||

| Taper / Speed / Power | RPM/kW | BT50 / 6,000 – 22 / 26kW | BT50 / 6,000 – 22 / 26kW | ||||||||||||||||

| Feedrate | Cutting | mm/min | 5 ~ 8000 | 5 ~ 8000 | |||||||||||||||

| X / Y / Z / W axis G00 | m/min | 10 / 10 / 10 / 2 | 8 / 8 / 10 / 1 | ||||||||||||||||

| Accuracy (JIS 6338) | mm | Positioning ±0.015 / full travel; Repeatability ±0.003 Rail Level accuracy 0.01 / 1000 | |||||||||||||||||

| ATC & Tool Magazine | Capacity / Dia | mm | 32 Pcs / Max. dia Ø125 (full tools); Ø220 (Adjascent pocket empty) | ||||||||||||||||

| Max tool weight / Length | kg/mm | 20kg / 400mm | 20kg / 400mm | ||||||||||||||||

| Tool selection | Free position take shortest direction / M24 P3.0-45° | ||||||||||||||||||

| Power / Pneumatic | 60 ~ 70KVA / 6.5kg/cm² | 60 ~ 70KVA / 6.5kg/cm² | |||||||||||||||||

| Machine Size | Length | mm | 9400 | 11400 | 13400 | 15400 | 9400 | 11400 | 13400 | 15400 | 11400 | 13400 | 15400 | 11400 | 13400 | 15400 | 11400 | 13400 | 15400 |

| Width | mm | 7300 | 7700 | 8100 | 8500 | 9100 | |||||||||||||

| Height | mm | 7500 (8400) | 8400 (9300) | ||||||||||||||||

| Machine Weight (appr.) | ton | 52 | 57 | 62 | 67 | 55 | 60 | 65 | 70 | 63 | 68 | 73 | 65 | 70 | 75 | 70 | 75 | 80 | |

Quality Service & Support

Our highly-trained staff is here and ready to service CNC machines. Amera-Seiki also carries an industry-leading parts inventory.

Our Services

Innovative CNC Technology

Amera-Seiki constantly evolves to provide you with the latest in machine productivity and features. We remain on the cutting edge of machine tool technology.

About Us

Explore Our Machines

Amera-Seiki has decades of experience building a large variety of CNC machines. No matter your need, we have the machine.

Our Machines