Vertical Bridge Gantry Mills

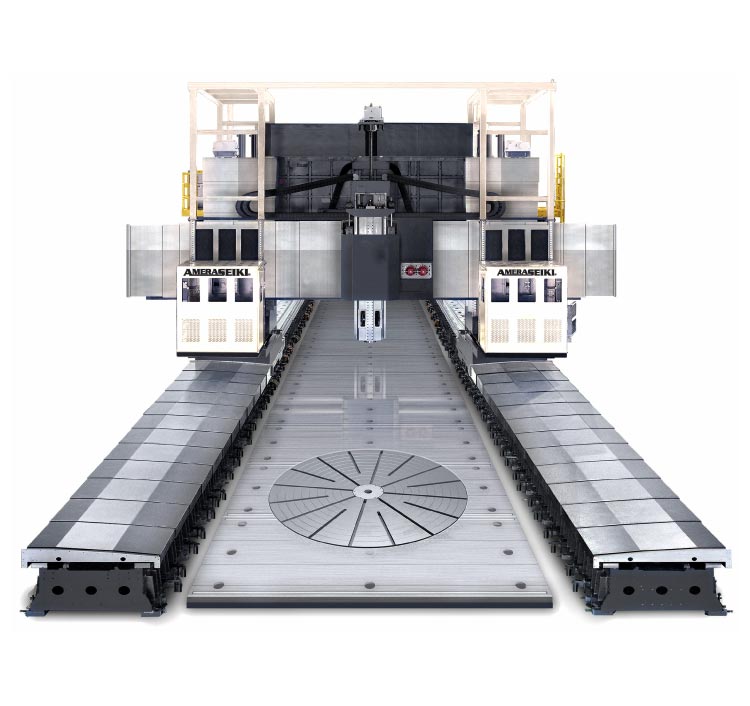

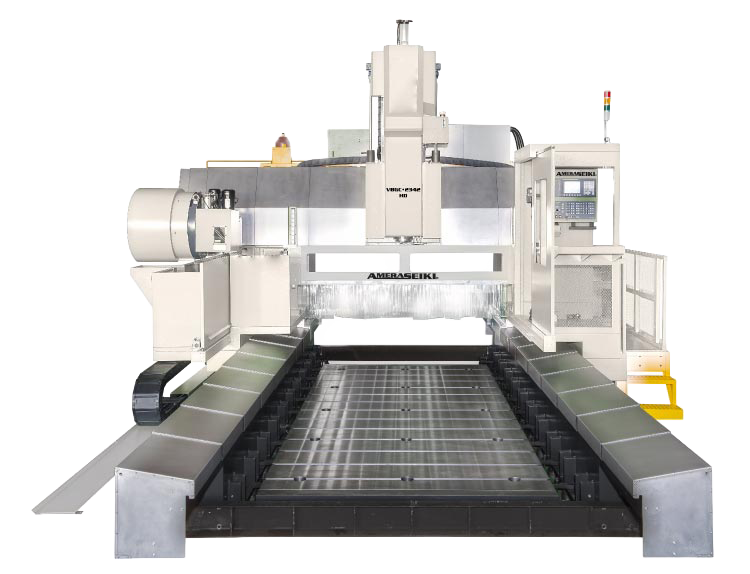

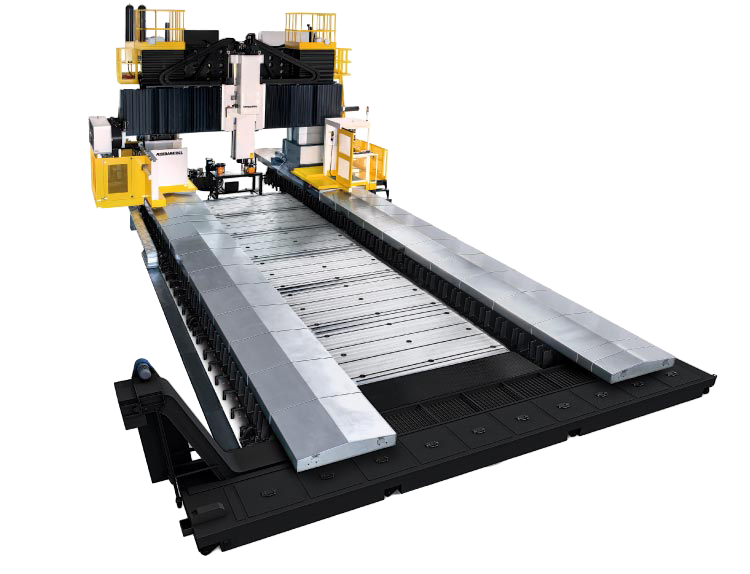

If you need more than six meters of X-axis travel on a bridge mill, look no further than the Amera-Seiki VBG Series Vertical Bridge Gantry Mill machine. By utilizing a fixed table and a moving bridge, we can generate huge X-axis travels. As an added benefit, since the table doesn’t move, you’ll be able to work on long pieces while only needing about half the floor space of a machine with a moving table!

Many shops find our cnc gantry mill machines simpler and faster for loading and unloading their workpieces because they can simply move the bridge out of the way during this procedure. And if you really want to increase your speed and efficiency, ask us about adding a dual-ram option. We even offer a twin-bridge option so you can machine two areas of the workpiece at the same time!

Amera-Seiki’s VBG Series Gantry bridge mills:

- We offer huge travels! X-Axis travels from 6 to 36 meters! Y-Axis travels from 2.4 to 5.4 meters! Z-Axis up to 2 meters with 2 meters of W-Axis available as well!

- 5-Axis Simultaneous machining is also available on these machines with Fanuc, Siemens or Heidenhain controls with up to 24,000 RPM utilizing HSK tooling.

- Need a rotating table within the floor table? We can do that!

- With our helical gear drive system, we offer the tightest rack-and-pinion for X-Axis travel!

- Need to increase your speed and/or efficiency? Ask us about our dual ram capability!

Equipment To Rave About

Vertical Bridge Gantry Mill Specifications

| Item | Unit | VBG-24 | VBG-28 | VBG-32 | VBG-36 | VBG-42 | VBG-48 | VBG-54 | |

|---|---|---|---|---|---|---|---|---|---|

| Distance Between Columns (withought splash guard) | mm | 2450 | 2850 | 3250 | 3650 | 4250 | 4850 | 5450 | |

| Floor Table | Length | m | 6 to 36 in one meter increments | ||||||

| Width | mm | 1600 | 2000 | 2400 | 2800 | 3400 | 4000 | 4600 | |

| T-Slot | Width x Pitch | mm | 28 x 500 | ||||||

| Travel | X-Axis | m | 6 to 36 in one meter increments | ||||||

| Y-Axis | mm | 2400 | 2800 | 3200 | 3600 | 4200 | 4800 | 5400 | |

| Z-Axis | mm | 1100 (1400) | 100 (1400, 1500-2000) | ||||||

| Spindle | Nose to Table | mm | 1220 – 2320 (2620) according to floor level | ||||||

| Center to Column | mm | 427 | 473 | ||||||

| Taper / Speed / Power | kw/RPM | BT-50 / 6000 / 22/26 | |||||||

| Feedrate | X / Y/ Z Cutting Speed | mm/min | 5 – 6000 | ||||||

| X / Y / Z Feedrate | m/min | 10/10/12 | 8/10/12 | 8/8/12 | 6/8/10 | ||||

| ATC & Tool Magazine | Capacity / Diameter | mm | 32 pcs / Ø125 (full tools) / Ø220 (adjascent pocket empty) | ||||||

| Max. Tool Weight / Length | kg/mm | 20kg / 400mm | |||||||

| Tool Selection | Take Shortest Direction / M24 P3.0 – 45° | ||||||||

| Power/Pneumatic | kva | 60 – 100 kva / 6.5 kg/cm² | |||||||

| Maximum Table Load | kg/m² | 3000 | |||||||

| Machine Size | Length | m | 13.5m to 43.5m in one meter increments | ||||||

| Width | m | 6.5 | 6.9 | 7.3 | 7.7 | 8.1 | 8.5 | 8.9 | |

| Height | m | 6.7 (7.5) | |||||||

| Machine Weight (approx) | ton | 50 + 2/m | 60 + 2/m | 70 + 2.5/m | 80 + 2.5/m | 90 + 3/m | 100 + 3/m | 110 + 3.5/m | |

Quality Service & Support

Our highly-trained staff is here and ready to service CNC machines. Amera-Seiki also carries an industry-leading parts inventory.

Our Services

Innovative CNC Technology

Amera-Seiki constantly evolves to provide you with the latest in machine productivity and features. We remain on the cutting edge of machine tool technology.

About Us

Explore Our Machines

Amera-Seiki has decades of experience building a large variety of CNC machines. No matter your need, we have the machine.

Our Machines