API Pipe Coupling Solution

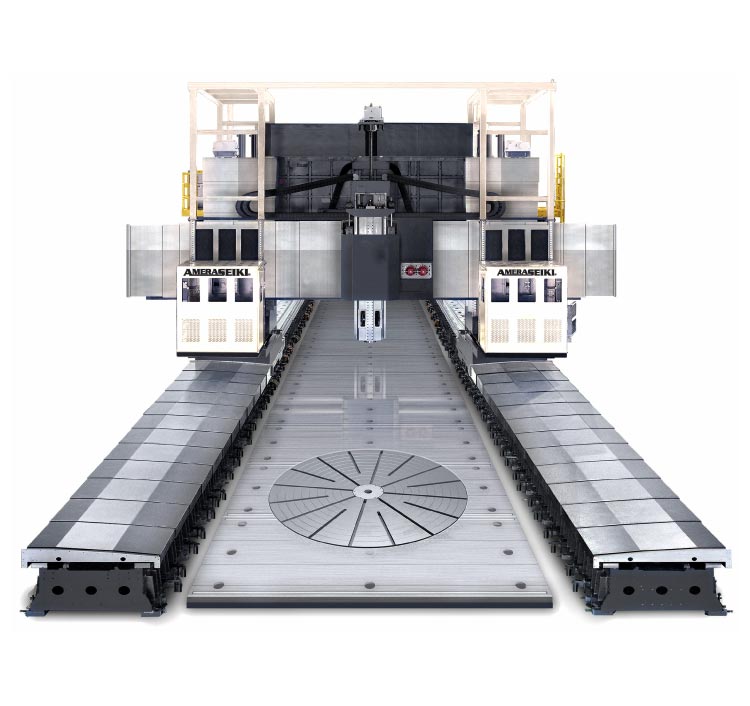

Ultimate Threading Machine (UTM)®

The UTM is an industrial pipe threading machine designed to solve problems faced for more than (4) decades.

Our revolutionary patented pipe coupling solution is a one-of-a-kind machine.

- Best option for API 8-10 round couplings and buttress threading

- No more bird nest means better threads, less scrap and makes it safer for operators handling the couplings.

- No de-burring saves labor and money.

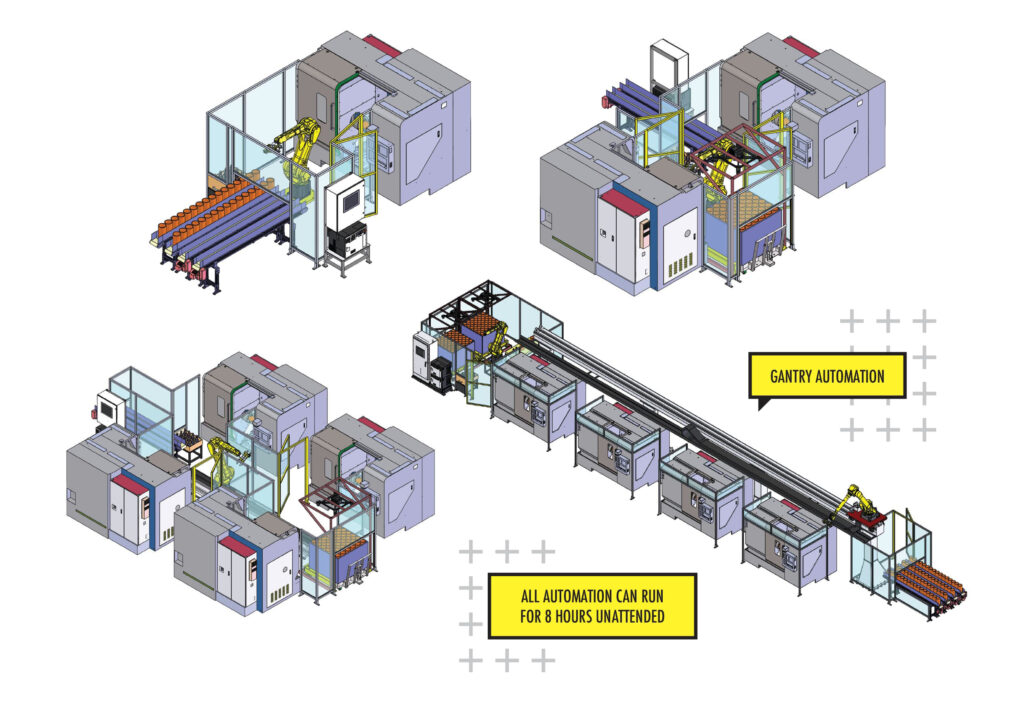

- Easy to automate to run (8) hours, unattended lights out with no labor.

- Very short ROI for fast payoff and maximum profit (normally less than a year).

- Order today and take delivery of your “coupling solution” in 6-8 months.

Innovative Technology

With this new patented solution, you’ll never have a bird nest again. This has been an issue with industrial pipe threading machines for couplers and we’ve finally solved it. With this innovation alone, we’ve made the thread perfect and the job safer while also reducing the scrap and no deburring.

Bird Nest from Standard CNC

Single Point Threading

Chips from our New UTM

Coupling Solution

Automation Made Easy.

Make Profit Quicker.

The UTM can be fully automated to process pipe couplings, reducing your labor expenses significantly. Expect an ROI within 6-8 months of use, running unattended for (8) hours, compared to standard CNC lathes cutting single point threads creating bird nest and much more scrap.

Equipment To Rave About

Specifications

| ITEM | Model | AMERA-SEIKI UTM-12 | AMERA-SEIKI UTM-20 |

|---|---|---|---|

| CONTROL | FANUC | Oi-TF (Opt 31i) | |

| MACHINING CAPACITY | Swing Over Bed | 660mm | 800mm |

| Max Turning Diameter | 300mm | 510mm | |

| MAIN SPINDLE | Spindle Nose | A2-8 | A2-11 |

| Spindle Bore | 102mm | 165mm | |

| Spindle Speed (RPM) | 3000rpm | 660rpm | |

| CHUCK SIZE | 12″ | 20″ | |

| TRAVEL | X Axis | 500mm | 700mm |

| Z Axis | 650mm | 750mm | |

| THRUST | X Axis Thrust Force | 3282kgf | 4200kgf |

| Z Axis Thrust Force | 4257kgf | 5300kgf | |

| FEEDS | X Axis Rapid Traverse | 10M/min | |

| Z Axis Rapid Travers | 10M/min | ||

| MOTORS | Main Motor | FANUC A25 Spindle Motor 37kw/50 HP | |

| X Axis Servo Motor | FANUC A22 Spindle Motor 4.0kw/22Nm | ||

| Z Axis Servo Motor | FANUC A30 Spindle Motor 7.0kw/30Nm | ||

| Lubrication Pump | 30W | ||

| Coolant Pump | 70 Bar/1,000psi | ||

| Hydraulic Tank Pump | 5hp (3.7kw) | ||

| MILLING SPINDLE | Taper | CAT-50 (BIG PLUS) | |

| Max Speed | 3000 RPM | ||

| Motor | FANUC A12 Spindle Motor 15kw/20 HP | ||

| TANK CAPACITY | Hydraulic Tank (optional) | 70L | |

| Lubrication Pump | 2L | ||

| Coolant Tank | 250L | ||

| BALL SCREW | X Axis Diameter | 40mm/Pitch 10 | |

| Y Axis Diameter | 40mm/Pitch 10 | ||

| MEASUREMENT | Length x Width x Height | 3000mm x 2300 x 2300mm | 3000mm x 2500 x 2300mm |

| Weight | 8000kg/17,600lbs | 8800kg/19,360lbs | |

Quality Service & Support

Our highly-trained staff is here and ready to service CNC machines. Amera-Seiki also carries an industry-leading parts inventory.

Our Services

Innovative CNC Technology

Amera-Seiki constantly evolves to provide you with the latest in machine productivity and features. We remain on the cutting edge of machine tool technology.

About Us

Explore Our Machines

Amera-Seiki has decades of experience building a large variety of CNC machines. No matter your need, we have the machine.

Our Machines